rockwell hardness test lab uh|rockwell hardness testing standards : chain store The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied . webThe Good Doctor: Created by David Shore. With Freddie Highmore, Richard Schiff, Hill Harper, Christina Chang. Shaun Murphy, a young surgeon with autism and Savant .

{plog:ftitle_list}

2004 | Classificação etária: 16 | 1h 43min | Terror. Você mataria para viver? É isso que dois homens precisam responder quando são raptados por um assassino em série e .

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the .

cobb sizing test

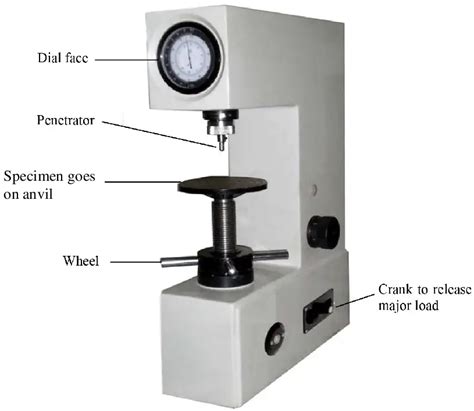

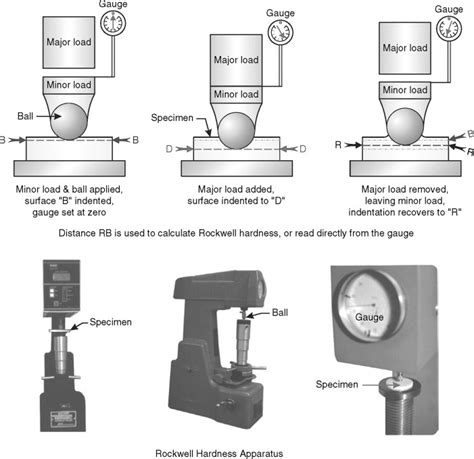

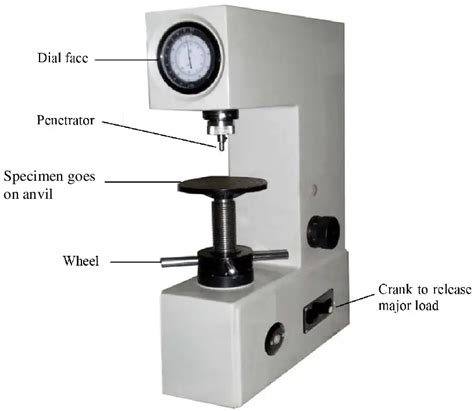

Rockwell hardness tester presents direct reading of hardness number on a dial provided with the machine. Principally this testing is similar to brinell hardness testing. It differs only in diameter and material of the indenter and the applied .In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .

rockwell hardness testing standards

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a .

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for . The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens and harder material. This hardness test is preferred because it is simple, easy and relatively nondestructive .

rockwell hardness testing procedure

rockwell hardness testing definition

Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated .

Portable Rockwell hardness testers are available, which allow for on-site or field hardness testing. This is advanta-geous for applications where it is not feasible to transport samples to a laboratory or for situations that require imme-diate hardness assessment. Portable Testing 1.1

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

Designed to execute various hardness scales within a single machine, typically for higher loads (>5kgf), these testers encompass all comprehensive Vickers, Knoop, Rockwell, and Brinell scales. Adhering to ISO 6506, 6507, 6508, and 4545, as well as ASTM E18, E10 & E92 standards, the UH4000 series ensures complete hardness testing capabilities.Page 6 of 13 Results Rockwell Scale C Scale B Scale A 150kgf 100kgf 60kgf Hardness Testing Rockwell Testing Scale C set to 150Kg Speciemen used in test Size of indent Z-specimen C10 Z4-specimen C34 Hardness Testing Rockwell Testing Scale B set to 100Kg Speciemen used in test Size of indent Z-specimen B95.5 Source of errors • Impact of .By using a test block, Rockwell hardness testers can be calibrated for optimal precision. All of Corporation’s test blocks to ASTM E18, ANSI (NCSLZ540-1, (ISO) 10012-1, ISO/IEC 17025, and ISO 6508, and they are certified in our ISO/IEC 17025 accredited laboratory. Each test block is hand lapped and diamond polished to a mirror finish, and .1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell .

• Laboratory and workshop testing • Sample testing or quality control testing • Steels, non-ferrous metals • Cemented carbide, ceramics, stainless steels The UH250 Universal Hardness Tester contains all standard hardness testing methods between 9.81 - 2452 N. The system is designed with high-quality mechanical componentsThe Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. How Rockwell Hardness Gets Measured.

Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell scale being used (e.g., 60 kgf for the Rockwell A scale, 150 kgf for the Rockwell C scale). . LABORATORY MANUAL FOR HARDNESS TEST. March 2019; March 2019; Authors: Ifeyinwa Obianyo. Nile University of Nigeria, Abuja; Download file PDF Read file. . Rockwell hardness testing machine.

II. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation.See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload . Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method.

1. Rockwell hardness test (scales A, B & C) methods : IS:1586-1988 Viva Questions: 1. What is Hardness? 2. What is the significance of minor load in Rockwell method of hardness testing 3. What are the advantages and limitations of Rockwell method of hardness testing 4. Where are Rockwell hardness test and Brinell hard test employed 5.

rockwell hardness testing advantages

In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine.Rockwell hardness test sesuai ISO 6508 / ASTM E18. . Dengan bantuan kedalaman lekukan permanen h, Rockwell hardness (HR) kemudian dapat dihitung menurut rumus yang ditentukan dalam standar ISO 6508 dengan mengacu pada skala Rockwell yang diterapkan. Prosedur uji .The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables and conversion charts for you. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; Our History; . Rockwell C Hardness Range

5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial

Rockwell Hardness Test Lab Object Background: The Rockwell hardness test is an indentatio To determine the hardness of metallic materials by Rockwell Hardness Tester n test which is nothing more than ndentation. The test measurement of resistance of a material to permanent i consists of forcing a steel ball or diamond cone into the material .Ordinary versus superficial In reality, there are two separate kinds of Rockwell test procedures. The Regular method and the Superficial method are these. The Regular technique is often referred to as the Rockwell method (AKA Super Rockwell method). 1. The Usual Approach Since this is how the Rockwell test is often conducted, 10 kgf is [.]

rockwell hardness tester

webOne community. We believe in diversity, equity, inclusion, and respect for all. Welcoming and supportive, Queen’s is a place to participate, thrive, and build lasting connections. Queen's is a leading, research-intense university in Canada offering an inclusive, transformative education that will prepare you to make a global impact.

rockwell hardness test lab uh|rockwell hardness testing standards